3D printing has changed how we make things. The technology lets people create objects from plastic, metal, and other materials right at home or in a workshop. 3D printers can make custom parts, toys, tools, and even artificial limbs, but they have real limits like the inability to print natural materials such as wood or cloth.

Some materials simply cannot be 3D printed due to their physical properties. The machines need specific types of materials that can melt and cool in layers. A 3D printer works best with plastics and certain metals that can be heated and shaped.

Geometric restrictions affect what can be printed. Very thin features like hair or small details may fail to print. The objects also need proper wall thickness and support structures to print correctly.

Exploring the Capabilities and Limits of 3D Printing

What 3D Printers Excel At

3D printers shine when it comes to making prototypes quickly. Imagine designing a new phone case and having a physical version in your hands within hours. This rapid prototyping speeds up design cycles and helps catch flaws early. They also make custom items easily. Need a special grip for a tool? A 3D printer can create it. This is a big deal for personalized medicine, too, with custom prosthetics and implants becoming more common.

Small-batch manufacturing is another area where 3D printing makes sense. For niche products or limited runs, it’s often cheaper than traditional methods. Plus, 3D printers can create complex shapes that are hard or impossible to make any other way. Think intricate gears, interlocking parts, or even artistic sculptures with fine details. It’s a fantastic educational tool, too. Students can design and print their own creations, which makes learning about design and engineering more engaging. For makers and hobbyists, 3D printing puts manufacturing power directly into their hands.

Where 3D Printers Fall Short

3D printing isn’t perfect. It’s generally slower than traditional manufacturing, especially when you need lots of copies. Material choices are also more limited. While the list of printable materials is growing, it’s still smaller than what you can use in factories. Cost is another factor. While some 3D printers are affordable, high-end machines and specialized materials can be expensive. Don’t forget about accuracy. While getting better all the time, 3D printing might not be as precise as other methods for some applications. Strength is another consideration. 3D-printed parts may not be as strong or durable as parts made in factories, though this depends a lot on the material. Often, 3D printed objects need extra work after printing, like removing supports, sanding, or painting. This adds time and effort.

The Future of 3D Printing

The future looks bright for 3D printing. Scientists are working on new, stronger materials, including metals, ceramics, and composites. Printing speeds are increasing, too. Expect to see faster and more efficient 3D printers in the future. Accuracy and resolution are also improving, meaning more detailed prints. We’re also seeing 3D printing being combined with other technologies, like AI and robotics, to create advanced manufacturing systems. Bioprinting, the ability to print living tissues and organs, is an exciting area of research, though it’s still early days.

3D Printing Capabilities and Limitations

| Capability | Limitation |

|---|---|

| Rapid Prototyping | Slow Printing Speed |

| Customization | Limited Materials |

| Small-Batch Production | Cost of High-End Machines/Materials |

| Complex Geometries | Accuracy/Precision |

| Educational Tool | Strength/Durability of Parts |

| Accessibility | Post-Processing Requirements |

| Medical Applications | Design Complexity |

| Art and Design | Environmental Impact |

| Functional Parts | Intellectual Property Concerns |

Can a 3D printer print on paper (documents)?

No, 3D printers don’t print on paper. They create three-dimensional objects by layering materials like plastic, resin, or metal. Traditional paper printers use ink to create images on flat sheets of paper.

Can a 3D printer print anything?

No, a 3D printer can’t print *anything*. There are limitations on the materials that can be used, the size of the object, and the complexity of the design. Also, some objects require specific material properties (like high tensile strength or electrical conductivity) that may not be achievable with current 3D printing technology.

Can a 3D printer print a 3D printer?

Theoretically, yes, *parts* of a 3D printer can be 3D printed. There’s even a project called RepRap that aims to create self-replicating 3D printers. However, not *everything* can be 3D printed (electronics, motors, etc.), so a fully functional 3D printer cannot yet be entirely 3D printed.

Can a 3D printer make anything?

Similar to the “print anything” question, 3D printers can make a *wide variety* of things, but not *everything*. Material limitations, size constraints, and design complexity are all factors. Think of it like a very versatile tool, but a tool nonetheless. It’s excellent for some jobs, but not suitable for others.

Can a 3D printer print silicone?

Yes, some 3D printers can print silicone. However, it often requires specialized equipment and materials. The technology for printing flexible materials like silicone is constantly improving.

Can a 3D printer print from a picture?

Not directly. A 2D picture needs to be converted into a 3D model before it can be printed. This usually involves using 3D modeling software or specialized image processing tools to create a 3D representation of the image.

Can a 3D printer scan an object?

No, a 3D printer itself cannot scan an object. Scanning requires a separate device, like a 3D scanner, which captures the shape and dimensions of an object. This scanned data can then be used to create a 3D model that *can* be printed.

Can a 3D printer make you money?

Yes, a 3D printer *can* make you money. You could offer 3D printing services, design and sell 3D-printed products, or use it for prototyping and manufacturing in your own business. However, like any business venture, success depends on various factors, including your skills, market demand, and business acumen.

Can a 3D printer be in a garage?

Yes, a 3D printer can be in a garage. However, you need to consider factors like temperature, ventilation, and workspace. Some materials may release fumes during printing, so proper ventilation is important. Also, temperature fluctuations in a garage could affect print quality.

Can a 3D printer make food?

While 3D food printing is an emerging field, it’s not yet widely used. Some 3D printers can create food items by extruding ingredients like chocolate, dough, or even pureed food. However, the technology is still developing, and the range of printable foods is limited.

Can a 3D printer print rubber?

Yes, some 3D printers can print rubber-like materials, often called flexible filaments. These materials have different levels of flexibility and are used for various applications, like gaskets, seals, or flexible phone cases.

Can a 3D printer make silicone molds?

Yes, you can 3D print molds that can then be used to cast silicone parts. This is a common technique for creating custom silicone products.

Can a 3D printer catch fire?

Yes, like any electrical device, a 3D printer *can* catch fire, though it’s relatively rare. This is usually due to electrical malfunctions, overheating, or issues with the materials being used. It’s crucial to use 3D printers safely, follow the manufacturer’s instructions, and never leave them unattended during printing.

Can a 3D printer print clear plastic?

Yes, some 3D printers can print clear or translucent plastics. The clarity depends on the material and the printing process. Resin printers, in particular, are known for producing highly clear prints.

Can a 3D printer copy an object?

Not directly. A 3D printer creates objects from a digital model. To “copy” an existing object, you first need to create a 3D model of it, usually using a 3D scanner or 3D modeling software. Then, you can print the model.

Can a 3D printer cause a fire?

Similar to the “catch fire” question, a 3D printer *can* be a fire hazard if not used properly. Electrical issues, overheating, or problems with materials can lead to fires. Always follow safety guidelines and supervise your 3D printer while it’s running.

Can a 3D printer print a house?

Yes, 3D printing of houses is becoming a reality. Specialized 3D printers can extrude concrete or other building materials to create the walls and structure of a house. This technology is still evolving but has the potential to revolutionize construction.

Can am 3D print?

I’m assuming you’re asking if you *can* 3D print. The answer is yes, if you have access to a 3D printer and the necessary skills and software. Many libraries, makerspaces, and online services offer 3D printing services.

Can you make a 3D printer at home?

Yes, you can build a 3D printer at home. There are many DIY kits and open-source designs available. However, it requires some technical skills and knowledge of electronics and mechanics.

Does a 3D printer use a lot of electricity?

The electricity consumption of a 3D printer varies depending on the size, type, and printing settings. Larger printers and those using higher temperatures will generally use more electricity. However, most desktop 3D printers don’t consume excessive amounts of power.

Key Takeaways

- 3D printers work with specific materials like plastic and metal but cannot print natural materials

- Objects need proper thickness and support structures to print successfully

- Current technology limits detail size and scanning abilities for complex items

Basics of 3D Printing

3D printing has become an important tool for design, manufacturing, and medicine. While it won’t replace all traditional manufacturing methods, it has unique benefits, especially for customization, quick prototyping, and creating complicated shapes. As technology improves and more materials become available, 3D printing will likely become even more important in how we create products.

3D printing creates objects by adding material layer by layer. This process lets people make complex shapes and parts from digital designs.

Understanding 3D Printing Technology

A 3D printer works like a robot that builds things from the ground up. It reads instructions from a computer file called a 3D model.

The printer moves in three directions: left-right, front-back, and up-down. This movement lets it put material exactly where needed.

Each printed layer sticks to the one below it. The layers stack up until the object is complete. Think of it like building with tiny bits of material one thin slice at a time.

Types of 3D Printing Processes

Fused Deposition Modeling (FDM) is the most common type. It melts plastic and puts it down in layers. This method works well for home use and basic parts.

Selective Laser Sintering uses a laser to melt powder into solid shapes. This method makes strong parts but needs expensive equipment.

SLA printing uses light to harden liquid resin. It makes very detailed parts with smooth surfaces.

Binder jetting sprays glue onto powder to make parts. This method can work with many materials including metals.

Materials Used in 3D Printing

Common Plastic Materials:

- PLA: Easy to print, made from corn starch

- ABS: Strong and heat-resistant

- Nylon: Flexible and durable

Advanced Materials:

- Metal powders

- Carbon fiber

- Ceramic particles

Different printers need specific materials. Some materials need high temperatures to melt. Others need special handling or storage.

The material choice affects how strong the final part will be. It also changes how easy it is to print.

Design for 3D Printing

Good 3D printing starts with proper design. The right design helps make printing easier and creates better final products.

Creating a 3D Model

A 3D model is a digital file that tells the printer what to make. 3D design software lets you create these models from scratch.

The model needs to be watertight. This means all parts connect with no gaps or holes. Think of it like a balloon – air can’t leak out anywhere.

Models use tiny shapes called polygons to make the 3D object. More polygons mean smoother curves but bigger files.

Understanding Printability

Not everything can be 3D printed. Walls need to be thick enough to print. Very thin parts might break.

Each printer has limits on size. Most home printers can make objects up to 400mm wide. Bigger items need to be split into smaller parts.

Material choice affects what you can print. Plastic works well. Wood and stone don’t print directly. Some printers only work with certain materials.

3D Design Software

Many tools can make 3D models. Popular choices include:

- SolidWorks for exact engineering

- Fusion 360 for home users

- Tinkercad for beginners

Basic shapes are easy to make. Complex designs need more skill. The software helps check if your model will print well.

Free tools work for simple projects. Paid software offers more features for complex designs.

Capabilities of 3D Printing

3D printers can create a wide range of items from simple plastic toys to complex metal parts. These machines build objects layer by layer with different materials like plastic, metal, and resin.

Complexity and Customization

3D printers excel at making complex shapes and structures. They can produce items with internal channels, hollow spaces, and intricate patterns that would be hard to make any other way.

Users can change designs quickly in software. This makes it easy to create custom items that fit exact needs. A person can adjust the size, shape, or features of an object before printing.

Some limits exist though. Natural materials like wood and stone cannot be 3D printed directly. The printers can only use special materials made for 3D printing.

Rapid Prototyping and Manufacturing

Companies use 3D printing to make test versions of products quickly. This helps them check designs before starting full production.

Engineers can print a prototype in hours instead of waiting weeks for traditional manufacturing. This speed lets them find and fix problems early.

The technology works well for making small batches of items. It costs less than setting up regular factory machines for short production runs.

Medical and Aerospace Applications

Medical teams use 3D printing to make custom prosthetic limbs and dental implants. These fit better because they match each patient’s exact measurements.

The technology creates precise surgical guides. Doctors use these tools to plan and perform complex operations more safely.

Aerospace companies print lightweight parts for aircraft. These pieces can have special shapes that make planes more efficient. They also use fewer materials and weigh less than traditional parts.

Physical Considerations

3D printing has key physical limits that affect what can be made. These limits include the size of parts, how smooth they can be, and which materials work best.

Size and Build Volume

Large flat sides work best for 3D printed parts. The printer’s build volume sets hard limits on part size.

Most home 3D printers can make objects up to 8 x 8 x 8 inches. Industrial printers can go much bigger.

The smallest features that can print well are about 0.8mm thick. Walls thinner than this may break or not print at all.

Surface Finish and Structural Integrity

Layer lines will show on printed parts. The layers stack up like tiny steps that you can see and feel.

Parts are strongest when force goes across the layers instead of along them. A printed cube is weaker if pulled up and down versus side to side.

Hot surfaces like print beds reach up to 100°C. This heat helps parts stick better and prevents warping.

Material Specifics and Limitations

Common materials for 3D printing:

- PLA: Easy to print but melts at low temps

- ABS: Tough but can warp

- PETG: Strong and water-resistant

- Nylon: Flexible and durable

Metal printing needs special printers that cost much more than plastic ones. Not all metals work for 3D printing.

Chemical safety matters when printing. Some materials give off fumes that need good air flow.

3D Printing in Practice

3D printing makes objects by adding material layer by layer. This method works in factories and homes to create many useful items.

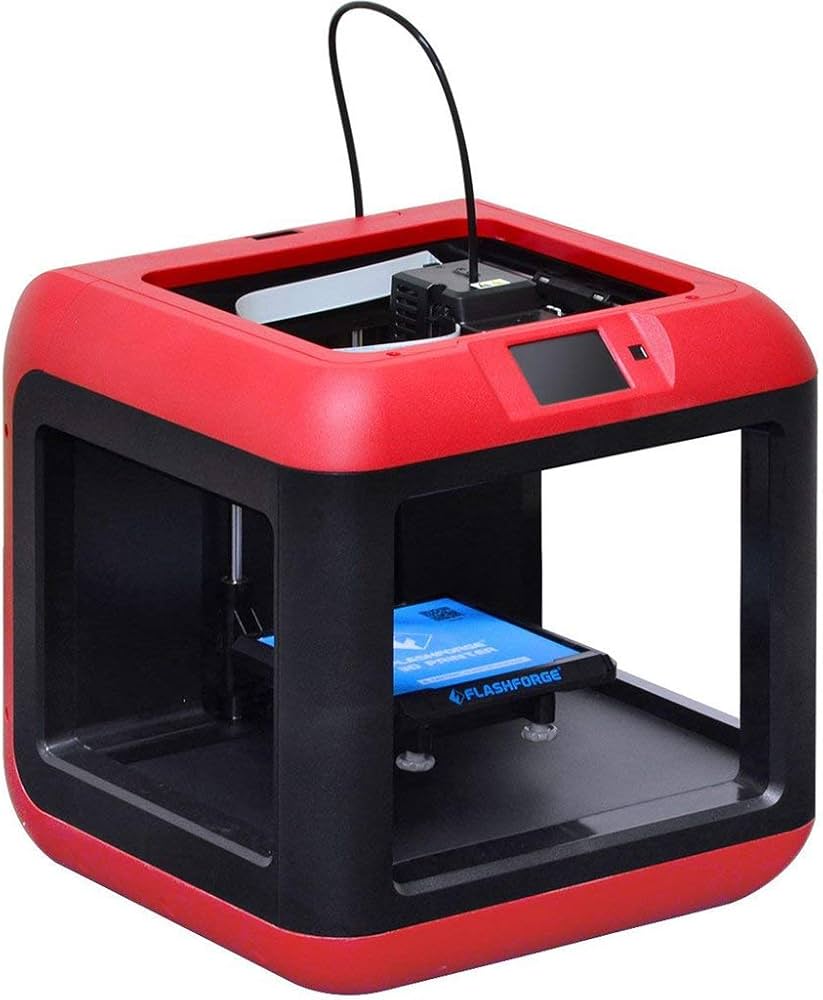

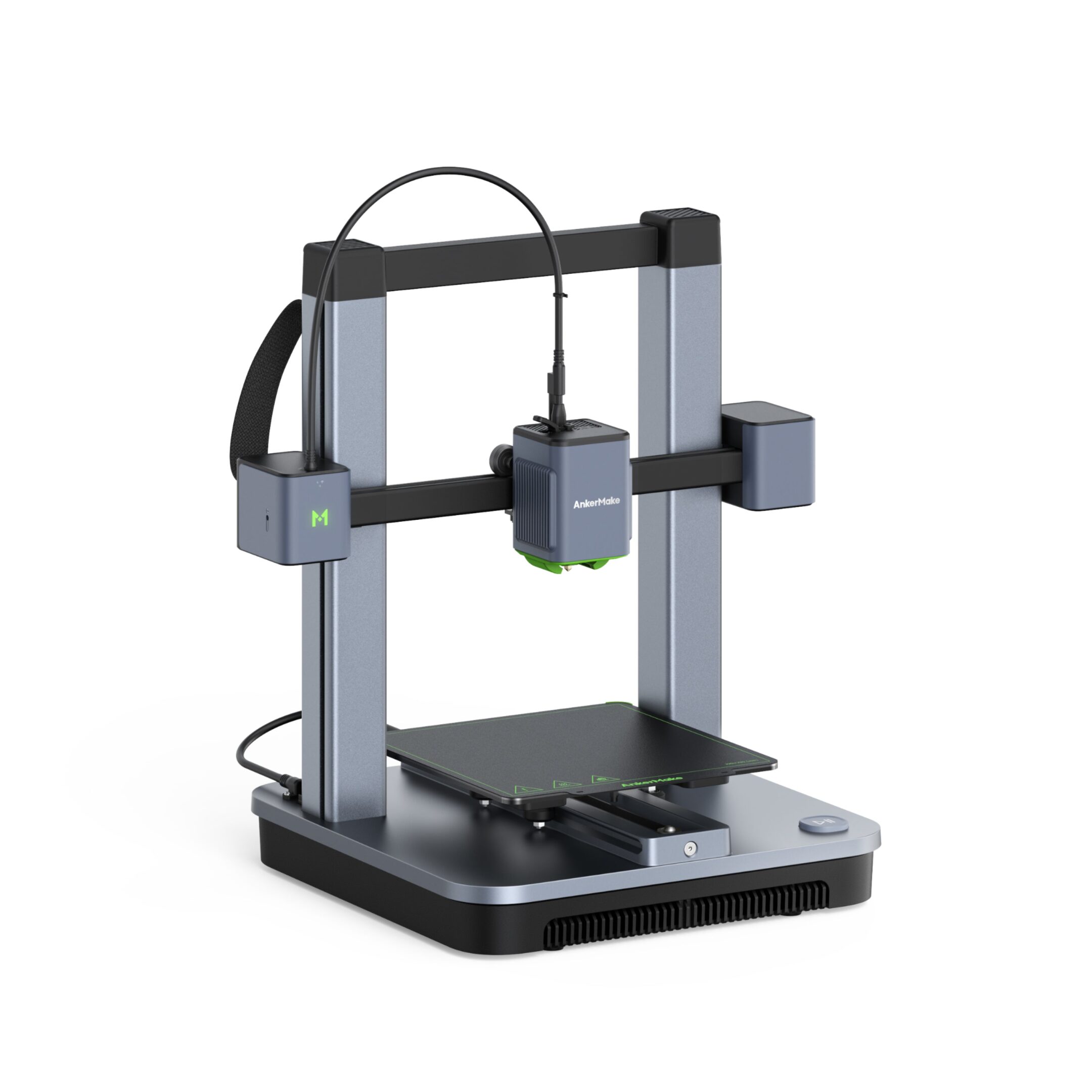

Industrial vs. Personal 3D Printing

Industrial 3D printers are large machines that make parts for cars, planes, and other big products. These printers cost a lot of money. They can print with metal and special plastics.

Home 3D printers are smaller and cheaper. They mainly use plastic materials. The print area is much smaller than industrial machines.

The main difference is size and speed. Industrial printers can make parts up to 1.8 meters long. Home printers usually make objects smaller than 30 centimeters.

From Prototypes to Finished Products

Many companies use 3D printing to test new product designs. This helps them find problems before making thousands of items.

Some products go straight from the printer to customers. Things like phone cases, toys, and replacement parts work well for this.

Not every item can be 3D printed. Things made of wood, cloth, or stone need different methods. Printed items might look like these materials but won’t work the same way.

The Impact of 3D Scanners

3D scanners take pictures of real objects and turn them into digital files. These files tell the printer how to make copies.

Simple scanners use phones or tablets to make basic 3D models. Professional scanners are more exact. They can copy small details that basic scanners miss.

Scanning helps fix broken items. If a part breaks, someone can scan the broken piece. Then they can print a new one that fits perfectly.

Limitations and Misconceptions

3D printing faces real limits in what it can make. Some common beliefs about these machines are wrong.

Technical and Material Constraints

Not every material works in 3D printers. Many designs need special support structures to print correctly. The walls must be thick enough to stay strong.

Printers can’t make parts with perfect detail. Most home printers make layers between 0.1 and 0.3 mm thick. Even the best machines can only go down to 0.025 mm.

Some shapes are hard to print. Parts that hang in the air need extra supports. Very thin or delicate features might break.

Common 3D Printing Misconceptions

Many people think 3D printers can make anything. This isn’t true. Each type of printer has limits.

Multi-color prints need special equipment. Basic printers use just one material at a time.

The cost of 3D printing has gone down a lot. Many people can now buy their own printer. But some still think only big companies can afford them.

Print quality depends on the printer type. FDM printers leave visible lines. SLA printers make smoother parts but cost more to run.

Specialized Applications of 3D Printing

3D printers create custom items for specialized hobbies and learning spaces. These tools bring creative ideas to life in new ways.

Cosplay and Custom Fashion

3D printed costumes and props let fans make exact copies of their favorite characters’ gear. Cosplayers print masks, armor pieces, and accessories that fit their exact size.

The process starts with digital designs. Users can adjust measurements to match their body shape. This makes each piece fit perfectly.

Common prints include:

- Helmets and face masks

- Armor plates and shields

- Weapon replicas

- Jewelry and accessories

Innovative Uses in Education and Art

Teachers use 3D printers to make learning more hands-on. Students can touch and examine printed models of things they study.

Popular classroom projects include:

- Animal skeletons

- Historic artifacts

- Math shapes

- Working machine parts

Artists print unique sculptures and jewelry. The technology lets them create shapes that would be hard to make by hand.

Schools save money by printing their own teaching aids. Students learn design skills while making useful items for class.

Future of 3D Printing

3D printing will change how companies make products. Many manufacturers will use cloud platforms instead of buying their own printers. This lets them make items anywhere in the world.

The aerospace industry will grow with 3D printing. Planes and drones need light but strong parts. 3D printers can make complex shapes that save fuel by reducing weight.

Housing costs may drop thanks to 3D printing. ICON already printed a house at a festival. More builders will use this tech to make homes faster and cheaper.

New materials will expand what 3D printers can make. Metal printing through sintering and melting will become more common. Plastic options will also grow beyond basic materials like PLA.

The tech will get faster and more exact. Bigger printers will make larger items in one piece. This means less assembly time and stronger finished products.

More people will use 3D printers at home. They’ll print replacement parts and simple items. But most complex products will still come from factories.

Key improvements coming soon:

- Better print quality

- Faster printing speeds

- More material choices

- Lower costs

- Larger print sizes

Frequently Asked Questions

3D printing lets people make all kinds of items at home or for business. The technology has grown a lot since the first industrial printers in 1988.

What can I create with a 3D printer that is commercially viable?

Many creators sell custom phone cases and jewelry on online marketplaces. Small businesses make replacement parts for machines and devices.

Local shops often need specialized tools or fixtures that 3D printers can make quickly. Artists create unique sculptures and decorative items to sell.

What are the limitations of 3D printing in terms of production scale?

3D printing works best for small batches of items. Large-scale production takes too much time compared to regular manufacturing.

The cost per item stays the same no matter how many you make. Traditional manufacturing gets cheaper with higher quantities.

Printers need frequent maintenance and monitoring. This limits how many items they can make each day.

What are the typical uses of 3D printers within a household?

Families print toys, game pieces, and educational models. Hobbyists make custom parts for their projects.

Home repairs become easier with printed replacement parts for appliances and fixtures. Kids learn design skills by creating simple objects.

What are the most common reasons for failure in 3D printing projects?

Poor bed leveling leads to items not sticking to the print surface. Wrong temperature settings cause weak or messy prints.

Bad quality control of materials can ruin prints. Incorrect design files often result in failed prints.

Which regulations govern items that are prohibited from 3D printing?

Laws ban printing weapons and other dangerous items. Many countries restrict printing trademarked or copyrighted designs.

Medical devices need special approval before printing. Some materials have safety rules about their use.

What are the different 3D printing technologies currently available?

FDM printers melt plastic filament to build objects layer by layer. SLA printers use light to cure liquid resin into solid parts.

Metal printers use lasers to fuse powder into strong parts. Multi-material printers can mix colors and materials in one print.

Does a 3D printer need a computer?

Yes, most 3D printers need a computer to control the printing process. The computer is used to load the 3D model, set the printing parameters, and monitor the print. Some printers can print directly from a USB drive, but still require a computer for the initial setup and file preparation.

Does a 3D printer need an enclosure?

An enclosure is not strictly *required* for all 3D printers, but it can be beneficial. Enclosures help regulate temperature, reduce noise, and contain fumes from certain materials. They are especially useful for printing with materials that are sensitive to temperature changes or that release potentially harmful particles.

Can you pause a 3D print and turn it off?

Most 3D printers allow you to pause a print. However, whether you can safely turn it *off* depends on the printer and the stage of the print. Abruptly turning off the printer during a print can cause layer shifts, warping, or other issues. It’s generally recommended to follow the printer’s specific instructions for pausing and stopping prints.

Can any 3D printer print carbon fiber?

No, not all 3D printers can print carbon fiber. Printing with carbon fiber requires specialized materials and equipment. Some high-end 3D printers are designed to handle carbon fiber filaments or composites, but these are generally more expensive.

Can any 3D printer print metal?

No, not all 3D printers can print metal. Metal 3D printing typically requires specialized technologies like Selective Laser Melting (SLM) or Direct Metal Laser Sintering (DMLS), which are significantly different from the processes used in common desktop 3D printers.