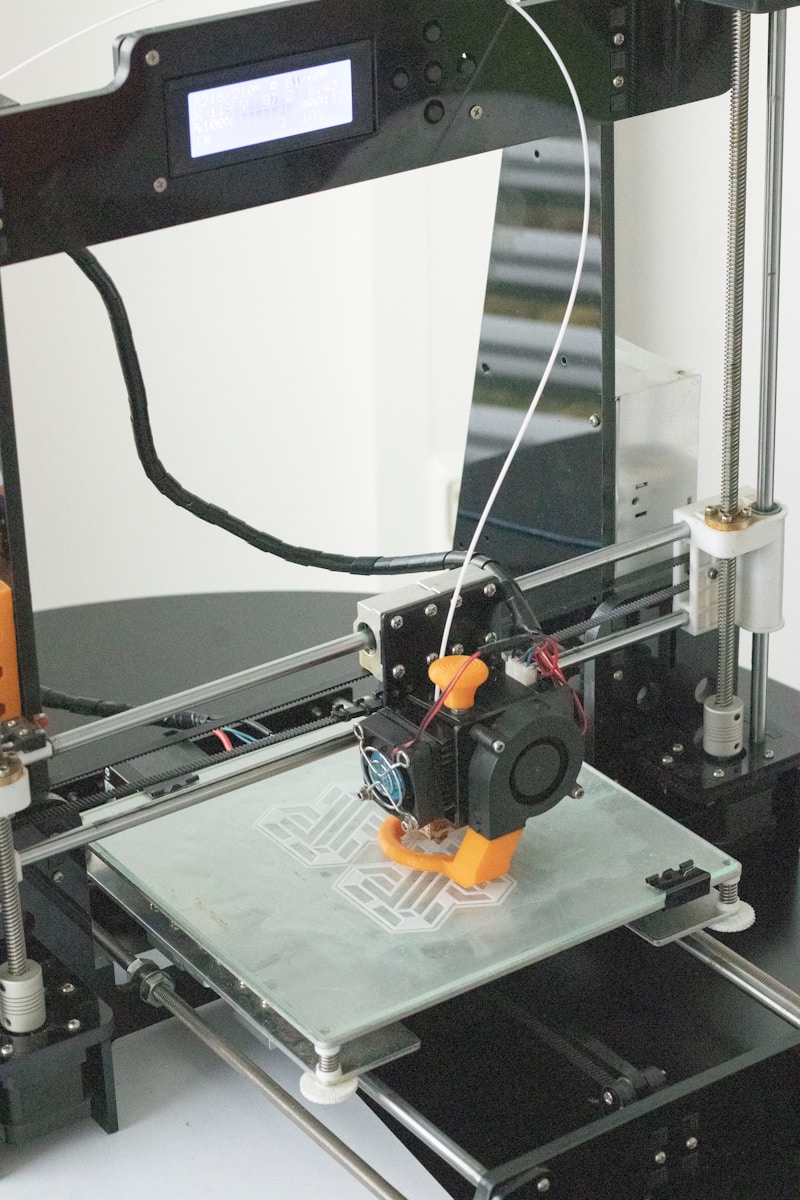

3D printing is an exciting technology that creates objects from digital designs. A common concern is whether 3D printers use a lot of electricity. Most 3D printers use between 50 and 150 watts of power while printing. This usage is similar to many household appliances like computers or light bulbs.

The exact amount of electricity a 3D printer uses depends on several factors. The size of the printer, the temperature settings, and the duration of the print job all play a role. For instance, maintaining higher temperatures for the hot end and the heated bed can increase power consumption.

Using 3D printers efficiently can help manage electricity costs. Simple steps such as optimizing print settings, using energy-saving modes, and choosing the right printer for your needs can make a difference.

Factors Influencing Energy Consumption

Several factors play a role in how much power a 3D printer uses:

- Printer Size: Larger printers with bigger build volumes and more powerful components generally consume more electricity than smaller desktop models.

- Heated Bed and Nozzle: The temperature and duration of heating for the print bed and nozzle significantly impact energy usage.

- Filament Type: Different filaments require varying temperatures for melting and extrusion, affecting energy consumption.

- Print Settings: Settings like layer height, print speed, and infill density can influence the duration of printing and thus energy usage.

- Cooling Fans: The use of cooling fans for the printed object and electronics adds to the overall energy consumption.

Typical Energy Consumption

The average energy consumption of a 3D printer varies depending on the model and usage. Here’s a general idea:

| Printer Type | Typical Power Usage (Watts) |

|---|---|

| Small Desktop | 50 – 150 |

| Medium Desktop | 150 – 300 |

| Large Desktop/Prosumer | 300 – 500 |

| Industrial | 500+ |

It’s important to note that this is just an estimation, and actual consumption may vary. You can find the specific power rating of your 3D printer in its documentation or specifications.

Do 3D Printers Use a Lot of Electricity?

Compared to other household appliances, 3D printers generally have moderate energy consumption. They use less power than devices like refrigerators, ovens, or air conditioners. However, their energy usage can still contribute to your electricity bill, especially with frequent or prolonged use.

To put it into perspective, a typical desktop 3D printer running for 10 hours might consume around 0.5 to 1.5 kilowatt-hours (kWh) of electricity. This is roughly equivalent to running a few light bulbs for the same duration.

Reducing Energy Consumption

If you’re concerned about the energy usage of your 3D printer, there are several steps you can take to reduce it:

- Optimize Print Settings: Use efficient settings like lower print speeds and reduced infill density when possible.

- Turn Off When Not in Use: Don’t leave your printer on standby for extended periods. Turn it off completely when not in use.

- Choose Energy-Efficient Filaments: Some filaments require lower temperatures for printing, which can save energy.

- Insulate the Print Bed: Adding insulation to the print bed can help maintain heat and reduce energy consumption.

By being mindful of your usage and adopting energy-saving practices, you can minimize the environmental impact and cost of operating your 3D printer.

Key Takeaways

- Most 3D printers use 50 to 150 watts of electricity.

- Power consumption depends on printer size, temperature, and print duration.

- Simple steps can help save on electricity costs.

Understanding 3D Printer Power Requirements

3D printers use different amounts of electricity based on their components and how long they run. Key factors include the type of power supply and the temperature of the heated bed and hot end.

Components and Power Usage

3D printers have several parts that draw power. The power supply converts high voltage AC to low voltage DC. They typically range from 50 to 150 watts.

- Hot End: Heats the filament to 205°C, using around 40-50 watts.

- Heated Bed: Keeps prints adhered at 60°C, using 70-120 watts.

- Stepper Motors: Move the printer parts, using about 15 watts each.

- Fans: Cool down parts, use around 2-5 watts.

- Mainboard: Controls the printer’s actions, uses about 5-10 watts.

- Display: Shows printer status, uses around 1-2 watts.

Factors Affecting Electricity Consumption

Several factors influence how much power your 3D printer uses.

- Print Time: Longer prints use more electricity.

- Temperature Settings: Higher temperatures for the heated bed and hot end increase power usage.

- Filament Type: Some materials need higher printing temperatures.

- Layer Height and Infill Density: Thicker layers and denser infill require more time and energy.

- Electricity Cost: Varies by location but can be estimated by kilowatt-hour (kWh) usage. For instance, a printer using 70 watts for 10 hours consumes 0.7 kWh.

By understanding these aspects, users can manage their 3D printer’s energy consumption more effectively.

Energy Efficiency and Cost-Saving Measures

3D printers can consume a noticeable amount of power, but there are ways to save energy and reduce costs. Using energy-efficient models and optimizing settings can make a big difference.

Optimizing Printer Settings for Energy Savings

Adjusting printer settings can significantly cut power use. Print speed and time are important factors. Slower speeds may use less energy overall. Reducing print resolution can help too, as it requires less energy to produce each layer.

Sleep mode is another useful feature. Many printers have this setting to save power when not in active use. Make sure it is enabled. Heating elements consume a lot of electricity, adjust bed temperatures depending on the material used.

Using a calculator can help you see the power usage. Monitor using a power meter to keep track of consumption. Tools like these help in understanding power needs and identifying where to save.

Selecting Energy-Efficient Printers and Practices

When choosing a printer, look for models with high energy efficiency. The Ender 3, especially the Creality Ender 3, is known for being efficient. Consider newer models as they often have better power-saving features.

DIY 3D Printer Enclosures are great for maintaining heat which reduces the need for the bed heater. Enclosures also help in controlling room temperature, making the printer work less hard.

Finally, compare electricity rates in your area. Some regions have different tariffs for day and night usage. By planning prints during off-peak hours, savings can be achieved.

By following these tips, you can use your 3D printer in an energy-efficient manner while keeping costs down.

Frequently Asked Questions

3D printers use different amounts of electricity depending on several factors. Below are answers to common questions about their electricity consumption.

How much electricity does a 3D printer consume per hour?

A 3D printer typically uses between 50 and 150 watts of electricity per hour. The exact amount depends on the printer’s size and settings.

What is the cost of electricity to operate a 3D printer for an extended period?

Running a 3D printer uninterrupted may cost between £0.24 and £0.96 per day, and between £87.60 and £346.75 per year, depending on electricity rates and usage.

Are there significant differences in power consumption between resin and filament 3D printers?

Yes, resin 3D printers often use more electricity due to the need for UV lights to cure the resin. Filament printers, on the other hand, mainly rely on heated beds and hot ends.

Can the use of a 3D printer significantly increase a household electricity bill?

Using a 3D printer modestly may cause a small increase in electricity bills. However, constant use can lead to noticeable changes.

How does the power supply rating affect a 3D printer’s electricity usage?

The power supply rating indicates the maximum power the printer can draw. A higher-rated power supply can support more powerful components, likely leading to higher electricity use.

Are certain models of 3D printers more energy-efficient than others?

Yes, some 3D printer models are designed to be more energy-efficient. Factors such as build quality, technology used, and energy-saving features help reduce power consumption.