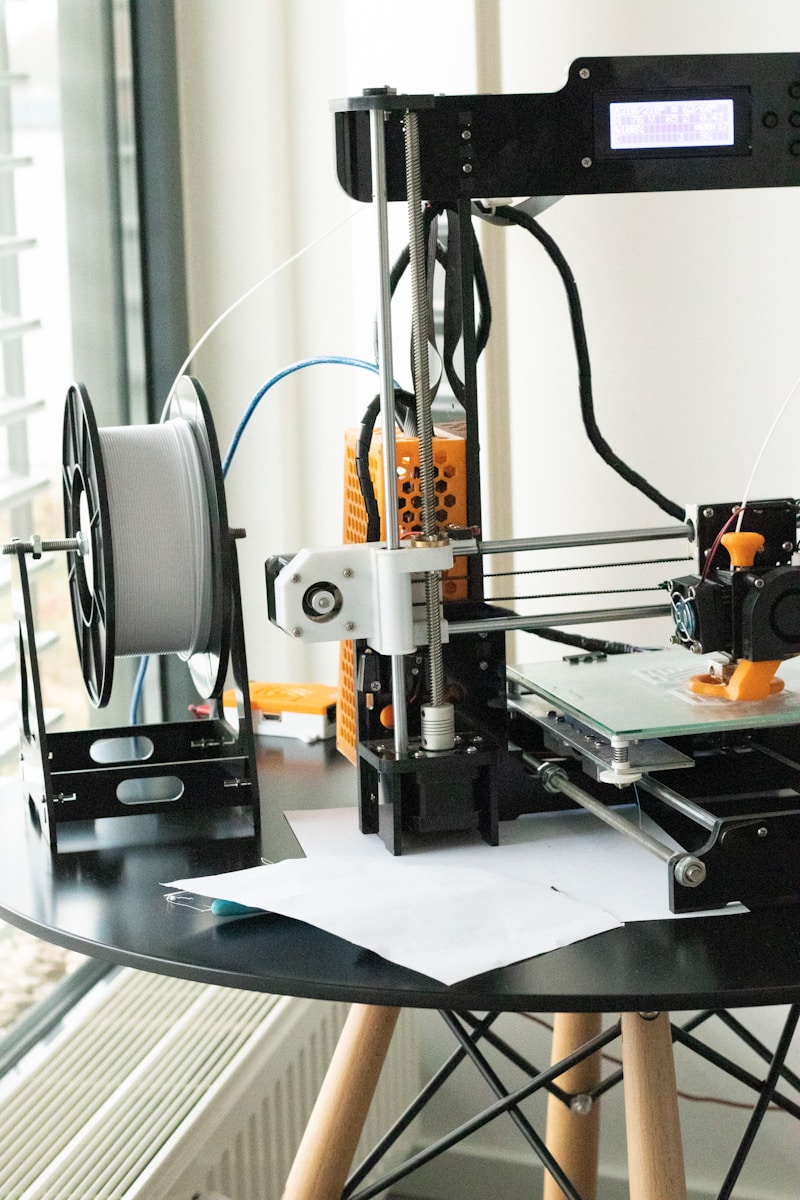

A 3D printer extruder is a vital part of any 3D printing process. It feeds filament into the printer, heats it until it melts, and then pushes it through a nozzle to form a 3D object layer by layer. The extruder includes several key parts that work together to ensure the filament is heated and then laid down accurately.

There are different types of extruders, such as direct drive and Bowden. Each type handles the filament in its own way. In a direct drive extruder, the motor and the extruder are close to the nozzle, providing better control. In a Bowden extruder, the motor is separate from the nozzle, making the setup lighter and faster.

The main components of a 3D printer extruder include the stepper motor, cold end, and hot end. The stepper motor powers the movement, while the cold end holds the filament and the hot end melts it. Together, they ensure precise control over filament extrusion.

3D Printer Extruder: The Heart of Your Creation

The Cold End: Feeding the Filament

The extruder’s cold end grips and pushes the filament towards the hot end. It usually consists of a stepper motor that drives a gear. This gear grabs onto the filament and feeds it into the hot end at a precise rate.

The Hot End: Melting and Laying Down

The hot end is where the magic happens. It consists of a heater block that melts the filament. Once melted, the molten plastic is forced through a nozzle, laying down the material layer by layer. A heat sink or fan cools the filament before it reaches the heater block, preventing premature melting.

The Nozzle: Shaping Your Design

The nozzle is the final point of control for the molten plastic. It comes in various sizes, affecting the print’s resolution and speed. Smaller nozzles provide finer details but slower printing, while larger nozzles are faster but result in coarser layers.

Types of Extruders

Direct Drive Extruder

The motor is directly connected to the extruder gears, providing more precise control and faster retractions. However, they can be heavier, limiting print speed.

Bowden Extruder

The motor is separated from the hot end and pushes the filament through a Bowden tube. This setup allows for lighter and faster print heads, but it can lead to slight inconsistencies with flexible filaments.

Extruder Maintenance

- Cleaning: Regularly clean the nozzle with a needle or brush to remove any debris or clogged material.

- Tightening: Make sure the extruder gears are properly tightened to ensure consistent filament flow.

- Lubrication: Some extruders benefit from lubrication to reduce friction and wear. Check your printer’s manual for specific recommendations.

Upgrading Your Extruder

Upgrading to a better extruder can improve print quality, speed, and material compatibility. Consider factors like direct drive vs. Bowden, filament compatibility, and print speed when choosing a new extruder.

Note: Always consult your printer’s manual for specific instructions and recommendations.

Key Takeaways

- The extruder feeds, heats, and pushes filament to create 3D objects.

- Direct drive extruders are close to the nozzle; Bowden extruders are separate.

- Main parts include a stepper motor, cold end, and hot end.

Extruder Types and Mechanisms

Extruders are vital in 3D printing. They determine how the filament is fed, heated, and deposited. Two main types are direct drive and Bowden extruders.

Direct Drive Extruders

Direct drive extruders place the motor and the extruder directly on the print head. This setup ensures precise control. The filament moves a short distance before reaching the hot end.

This type is known for high torque and maximum extrusion control.

- Flexibility: Direct drive extruders work well with flexible filaments like TPU.

- Precision: They offer excellent accuracy, reducing stringing and improving print quality.

- Durability: The setup can handle various filament materials.

- Weight: The print head becomes heavier due to the motor’s weight.

The extruder’s close proximity to the hot end reduces errors and improves retraction performance.

Bowden Extruders

Bowden extruders, in contrast, separate the motor from the print head and use a Bowden tube to guide the filament. This design places the extruder on the printer’s frame.

- Speed: Bowden setups offer faster printing speeds.

- Mass: The print head is lighter, leading to fewer vibrations.

- Retraction: Proper tuning is needed to manage retraction and avoid stringing.

- Compatibility: They work well with non-flexible filaments, like PLA and ABS.

The Bowden extruder’s remote placement reduces the weight on the moving parts, allowing smoother and faster movements during printing. This design helps in achieving quicker print times while maintaining good print quality.

Extruder Components and Functions

The 3D printer extruder consists of several parts that work together to feed, heat, and push filament through the nozzle. Key parts include the hot end and the cold end.

The Hot End

The hot end is where the filament melts before being extruded. Crucial components of the hot end are:

Heating Element: This part heats the filament to its melting point. It ensures that different materials like ABS, PLA, PETG, and TPU melt correctly.

Nozzle: This part allows the melted filament to exit and form layers on the print bed. They come in various sizes, affecting print speed and quality.

Thermistor: This temperature sensor monitors the heating element, ensuring the filament doesn’t overheat or underheat, maintaining optimal print quality.

Heat Break: This part ensures that heat doesn’t travel up to the cold end. It keeps the filament from melting prematurely, which helps in precise filament movement.

The Cold End

The cold end is responsible for feeding the filament to the hot end. Its main components are:

Stepper Motor: This motor drives the filament towards the hot end. It controls the movement and ensures consistent extrusion.

Gears: Gears grip the filament tightly, pushing it forward. They provide torque to move the filament at the right speed.

Cooling Fan: This fan cools the upper parts of the extruder, preventing clogs. It makes sure the filament stays solid before reaching the hot end.

Direct Drive/Bowden Extruder: In a direct drive, the cold end is directly attached to the hot end. Bowden extruders have a tube that guides filament from the cold end to the hot end, reducing weight on the print head.

Frequently Asked Questions

A 3D printer extruder plays a vital role in feeding, heating, and pushing filament to create 3D printed objects. Let’s answer some common questions to help you understand its workings better.

What are the different types of 3D printer extruders?

There are two main types of 3D printer extruders: direct drive and Bowden. Direct drive extruders have the motor close to the hot end, making them precise. Bowden extruders have the motor further away, making the setup lighter but sometimes less accurate.

How is filament fed into a 3D printer extruder?

The filament is pulled into the extruder by a drive gear or motor. This gear grips the filament tightly and pushes it towards the hot end, where it gets melted and extruded.

In what ways does a 3D printer extruder manage heat and melting?

The extruder uses a heating element to melt the filament. A temperature sensor ensures the filament melts at the right temperature. Fans help cool the filament quickly after it is extruded to form the final shape.

What functions are performed by the nozzle of a 3D printer extruder?

The nozzle directs the flow of melted filament onto the print bed. It determines the thickness of each layer, and its size affects the detail and speed of printing. Different nozzles can be swapped depending on the project requirements.

Can you explain the assembly process of a 3D printer extruder?

Assembly involves fitting together the drive gear, motor, hot end, and cooling fan. Each part is connected carefully to ensure the filament feeds smoothly and the temperature stays controlled. Instructions vary by model but usually follow similar steps.

What are the common issues faced with 3D printer extruders and how are they addressed?

Common issues include filament jams, inconsistent extrusion, and overheating. Regular cleaning and maintenance can prevent jams. Adjusting the tension of the filament feed can help with extrusion issues. Monitoring the temperature settings can avoid overheating.