Understanding the intricacies of how a color laser printer works is essential for anyone who interacts with this technology, whether at home or within an office environment. The process begins with a concept known as electrophotography or xerography, a technology that was pioneered in the mid-20th century by Gary Starkweather while working at Xerox. This process is at the heart of laser printing, enabling these printers to produce crisp text and vibrant images.

Electrophotography is a complex process involving several key steps. First, a laser beam scans the printer’s drum unit, which is coated with a photosensitive material. The beam selectively discharges certain points on the drum to create an electrostatic image. Toner, which is a fine powdered ink, is then attracted to the charged areas of the drum. The drum transfers the toner onto the paper as it passes through the printer. Since color laser printers work with multiple colors, this process is repeated for each toner color, typically cyan, magenta, yellow, and black, layering the tones to create the full spectrum of print colors.

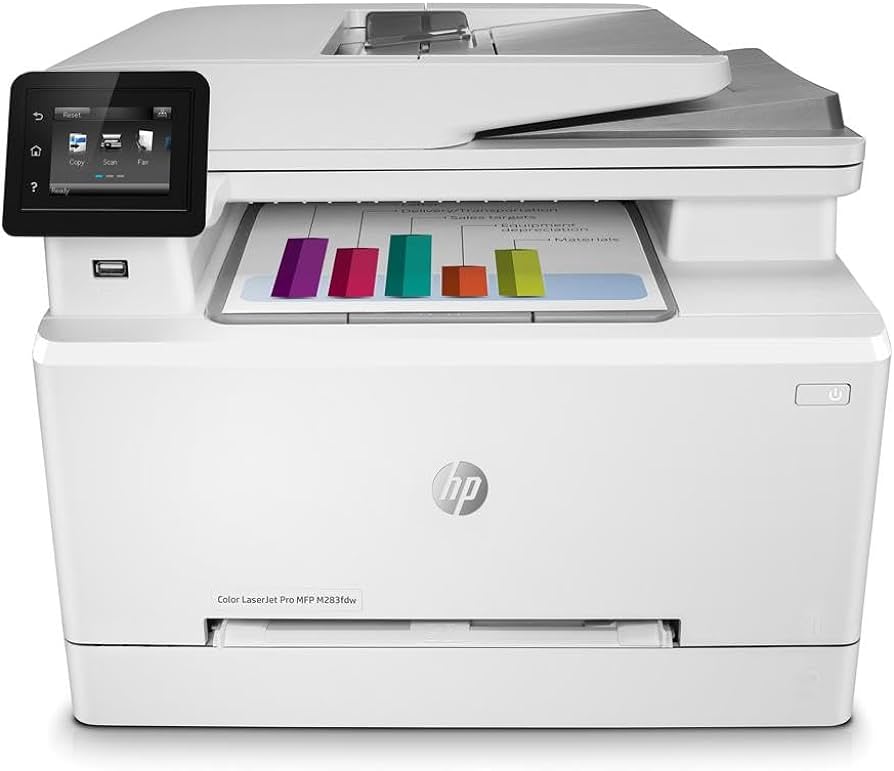

The accuracy and speed of laser printers make them a favored choice in settings where high-quality, efficient printing is needed. They are particularly well-suited for small businesses and office environments. Brands like HP, Canon, and Xerox have been leading the development of color laser printers, striving to improve the technology and make it more accessible to users.

Color Laser Printing: A Closer Look at the Technology

The Color Laser Printing Process: A Step-by-Step Guide

- Charging: The printer’s photosensitive drum receives a negative charge.

- Writing: A laser beam “writes” the image onto the drum, selectively neutralizing the charged areas.

- Developing: Toner particles, carrying a positive charge, are attracted to the neutralized areas of the drum, forming the image.

- Transferring: The toner image is transferred from the drum onto a piece of paper.

- Fusing: Heat and pressure fuse the toner to the paper, creating a permanent print.

Color Laser Printing vs. Inkjet Printing: Key Differences

| Feature | Color Laser Printer | Inkjet Printer |

|---|---|---|

| Print Technology | Electrostatic transfer | Ink ejection |

| Toner/Ink Composition | Dry powder | Liquid ink |

| Print Speed | Generally faster | Varies, can be slower for high-quality prints |

| Print Cost | Lower cost per page for high-volume printing | Higher cost per page, especially for color prints |

| Print Quality | Sharp text and graphics | Excellent for photos and color accuracy |

| Durability | More resistant to fading and smudging | Less resistant to fading and smudging |

| Best Suited For | Office documents, high-volume printing | Photos, graphics, low-volume printing |

Color Laser Printers: A Breakdown of Key Components

- Laser Beam: The laser beam “writes” the image onto the photosensitive drum.

- Photosensitive Drum: The drum holds the electrostatic charge and attracts toner particles.

- Toner Cartridges: Contains toner, a fine powder used to create the image.

- Transfer Belt: Transfers the toner image from the drum to the paper.

- Fuser Assembly: Applies heat and pressure to fuse the toner to the paper.

Key Takeaways

- Color laser printers create images via electrophotography, a process that uses laser technology to produce an electrostatic image.

- The process involves applying toner to a drum unit and transferring it to paper, repeating the step for each color.

- These printers are preferred in professional settings for their efficiency and high-quality output.

Fundamentals of Color Laser Printing

Color laser printers transform digital data into vibrant printouts with speed and precision. They use a complex process involving electrical charges and interactions between multiple components to produce documents and photos on paper.

Understanding the Printing Process

When someone sends a document from a computer to a color laser printer, the printer receives the data and starts preparing to create the print. A laser beam moves back and forth across a photosensitive drum inside the printer, altering the drum’s electrical charge to create a pattern. This pattern represents the image on the digital document.

Components and Functions

Key components of a color laser printer include the drum, toner cartridges, fuser, and corona wire. The drum has a coating that holds a static electrical charge. Toner cartridges contain powdered ink in cyan, magenta, yellow, and black. The fuser applies heat and pressure to bond the toner to the paper. The corona wire’s job is to give the drum a positive charge and attract negatively charged toner particles.

Color Integration in Laser Printers

Color laser printers combine cyan, magenta, yellow, and black to create a full spectrum of colors. During the printing process, the printer lays down toner for one color at a time, and each color layer is fused onto the paper. After all colors have been applied, the document emerges complete with all the combined colors.

Technological Comparisons

Compared to inkjet or dot-matrix printers, color laser printers are often faster and better suited for large volumes. They are different from photocopiers in that they receive electronic data directly from computers. While initially more expensive, laser printers offer advantages in speed and efficiency, making them a strong choice for workplace printing needs.