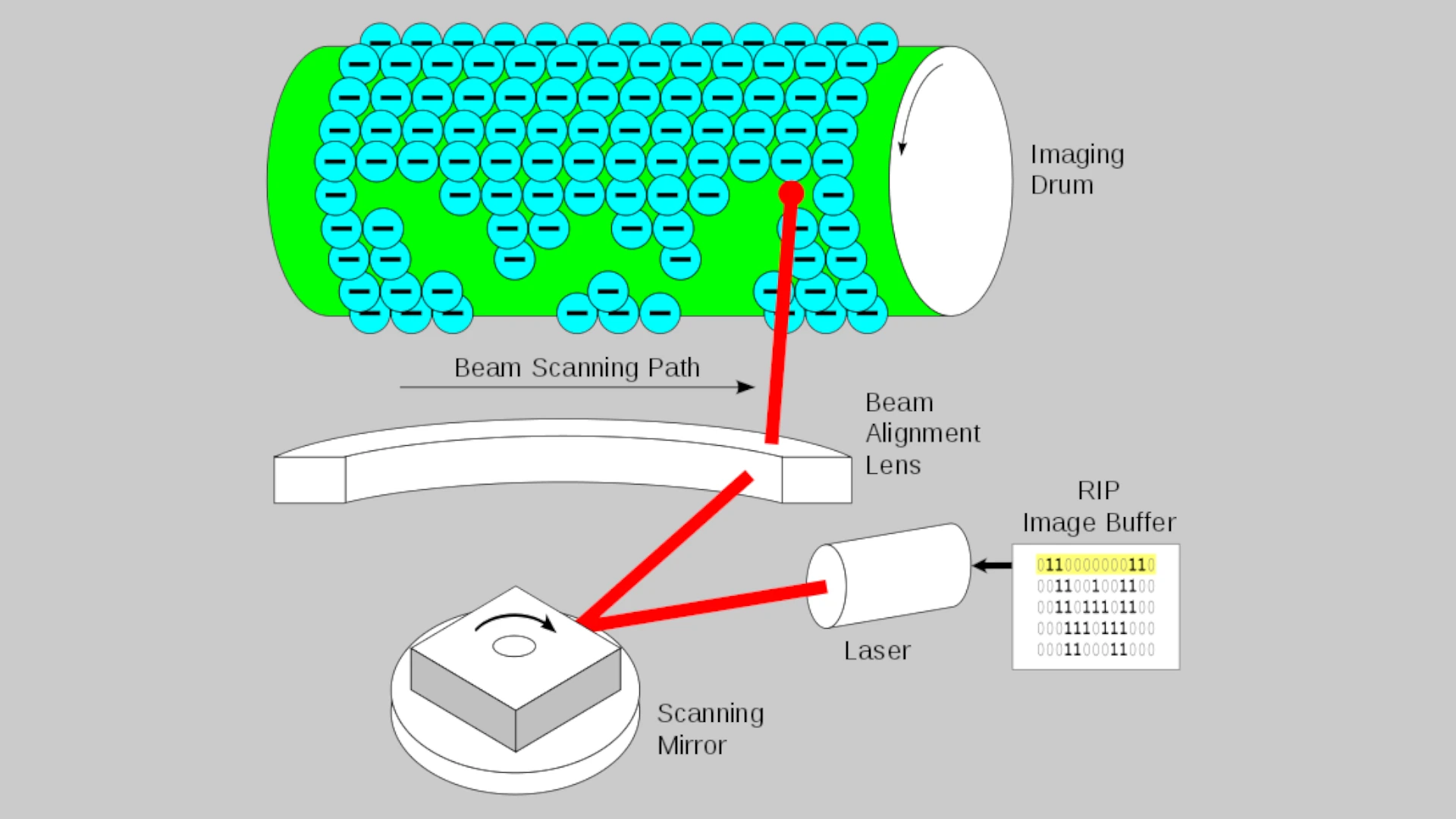

Printers, especially laser printers, depend on static electricity to take digital images and text from your computer and place them on paper. Static electricity charges the printer’s drum, making it attract toner particles in the shape of your document. This process allows for precise printing, creating high-quality images and text efficiently.

When the drum touches the paper, the toner transfers from the drum to the paper. The paper then passes through a fuser, which uses heat to permanently bond the toner to the paper. This method is both fast and accurate, making it a preferred choice for offices and homes.

The role of static electricity in this process is crucial. Without it, printers wouldn’t be able to control where the ink goes, affecting the quality of the print. Through this innovative use of physics, printers have become reliable tools for creating sharp, clear documents.

Image Credit: Dale Mahalko, CC BY 3.0 https://creativecommons.org/licenses/by/3.0, via Wikimedia Commons

Key Takeaways

- Printers use static electricity to transfer toner to paper.

- The drum attracts toner in the shape of the digital image.

- The fuser bonds the toner to the paper permanently.

Fundamentals of Static Electricity in Printing

Static electricity plays a crucial role in how laser and inkjet printers operate. It involves the movement and control of electrical charges to produce images and text on paper.

The Concept of Static Electricity

Static electricity is the build-up of electrical charges on the surface of materials. This occurs when electrons transfer from one object to another, creating an imbalance. Objects gain these charges through contact and separation, often rubbing together, known as triboelectric effect.

In printing, static electricity is essential for manipulating toner or ink. A static charge attracts particles to specific areas, enabling precise image and text formation on the page.

Static Electricity in Laser and Inkjet Printers

Laser printers use static electricity extensively. They rely on a photoreceptor drum that rotates through different stages of the printing process. The corona wire applies a uniform static charge to the drum. A laser then discharges areas of the drum to create an electrostatic image.

In contrast, inkjet printers utilize static electricity to control the fine droplets of ink expelled from the printhead. While not as central as in laser printers, static electricity helps maintain the accuracy and quality of droplet placement on the paper.

Differences Between Laser and Inkjet Printing Processes

Laser printers use a powdered toner. The corona wire charges the drum, and the laser creates the image by discharging areas. The charged toner sticks to these discharged areas. The drum then transfers the toner to the paper, which gets fused by heat.

Inkjet printers spray liquid ink through tiny nozzles. Controlled by electrical charges, the ink droplets form images and text on the paper. They don’t require heat to fix the image.

In summary, static electricity is vital in laser printers but also important in inkjet printers. Understanding these processes highlights the role of static electricity in achieving precise, high-quality print results.

Components and Mechanics of Printer Operation

Printers transform digital data into physical text and images using a combination of static electricity and specialized components. Understanding the role of each part and how they interact is essential for grasping the whole printing process.

The Photoreceptor Drum and Its Role

A photoreceptor drum, often made of a metal like selenium, is crucial in laser printers. Engineers charge it with a positive electric charge using a corona wire. Then, a laser beam selectively discharges specific areas of the drum, creating a negative image of the data to be printed. This process relies on static electricity to attract toner particles to the charged areas, forming an image on the drum. The drum then transfers this image to paper, using the charge difference.

Toner and Ink: Composition and Transfer

Toner in laser printers is a fine ink powder made from plastic particles mixed with coloring agents and other chemicals. Static electricity makes this toner stick to the negative charges on the photoreceptor drum. In contrast, inkjet printers use liquid ink. The printer sprays this ink onto paper through tiny nozzles. The toner or ink moves precisely to the areas needed to create text or images, ensuring clear and sharp prints by following the charge patterns on the drum.

Fusing Technology: Heat and Pressure

After the toner transfers to the paper, it must be fused to ensure durability. Fusing technology involves the use of heat and pressure to melt the toner particles and bond them to the paper. A fuser unit, comprising heated rollers, melts the toner powder, while the pressure roller presses the toner into the paper fibers. This process maintains the integrity of the print, preventing smudging and ensuring the printed images or texts are permanent and clear. The fusing mechanism is essential for producing long-lasting and high-quality prints.

Frequently Asked Questions

Printers use static electricity in several ways to create crisp and clear prints. Below are the key questions often asked about this process and its impact on different types of printers.

What is the role of static electricity in the operation of laser printers?

Laser printers use static electricity to transfer toner to paper. A laser beam creates a static electric charge on a drum. The charged drum then attracts toner particles. When the paper rolls over the drum, it picks up the toner.

How does static electricity contribute to the inkjet printing process?

In inkjet printers, static electricity is less central but still important. The printer charges tiny droplets of ink, which helps them form a precise pattern on the paper. This process ensures accurate and high-quality prints.

Can static electricity affect the quality of printed materials?

Yes, static electricity can impact print quality. Too much static can cause toner to scatter, leading to blurry images or text. Proper grounding and humidity control can mitigate these issues.

In what ways is static electricity utilized in photocopiers?

Photocopiers operate on principles similar to laser printers. They use static electricity to transfer toner to paper. A light exposes the original document, creating a static charge on a drum. The charged areas pick up toner, and the toner is transferred to paper to produce a copy.

How can static electricity build-up be managed in printing devices?

To manage static electricity build-up, maintain proper humidity levels around printers. Grounding the device also helps. Avoid placing printers near materials that generate static. Regular maintenance checks can prevent static-related problems.

What are the basic steps involved in the electrostatic printing process?

The main steps include:

- Data transfer from the computer to the printer.

- Creation of a static charge on a drum or belt.

- Attraction of toner particles to the charged areas.

- Transfer of toner from the drum to the paper.

- Fusing the toner to the paper using heat or pressure.